One of the primary priorities when designing ENSET balancing equipment is ensuring the safety of the operator and other personnel in the balancing zone.

Potential hazard sources may include contact with the rotating workpiece, ejection of the rotor components or balancing weights during rotation, detachment of the rotor from its supports, or the rotor bursting. The danger increases with an increase in rotor mass and rotation speed, but it can be reduced by a reliable protective enclosure used during balancing.

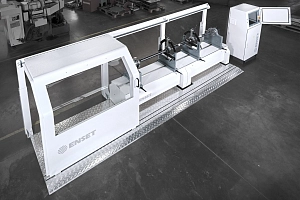

Protective enclosures for ENSET balancing equipment are key to safety in the workplace. The balancing cycle only starts upon automatic locking of enclosures constructed according to ISO 21940-23:2012.

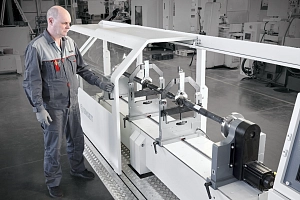

When designing the protective enclosure, ENSET specialists took into account all possible hazard sources, covering the rotor end drive shaft, drive belts, and the balancing zone. Thanks to the panoramic window, the machine operator can conveniently visually monitor spin of the rotor.

The reliable enclosure design with special heavy-duty triplex glass protects the machine operator in case of emergency situations related to rotor bursts during use. The enclosure moves on the linear guide rails for effortless opening.

Numerous tests and operations have shown that the protective enclosure can withstand the impact of ejected rotor parts, as well as balancing weights.

The use of the protective enclosure significantly reduces the likelihood of accidents that could result in injury to the balancing machine operator, other personnel, or damage to equipment in the workshop.

The ENSET protective enclosure can be customized for any balancing machine model as an optional add-on feature.

To learn more about ENSET Protective Enclosures and place an order, contact us at: +7 960 442-73-51