The world's first dynamic balancing machines were soft-bearing, with flexible supports. A few decades later, a new type of machine appeared – with rigid supports, or hard-bearing. Initially, they were not very accurate, but with the advent of new types of sensors and the development of electronic and digital technologies, the situation has changed dramatically. Hard-bearing machines quickly achieved and surpassed the accuracy of their soft-bearing predecessors, and a number of advantages of machines with rigid supports have made them the undisputed leaders among modern balancing equipment. Let's take a closer look at each type of machine, their design, and list the pros and cons of each design.

Soft-bearing (machines with malleable, pendulum supports)

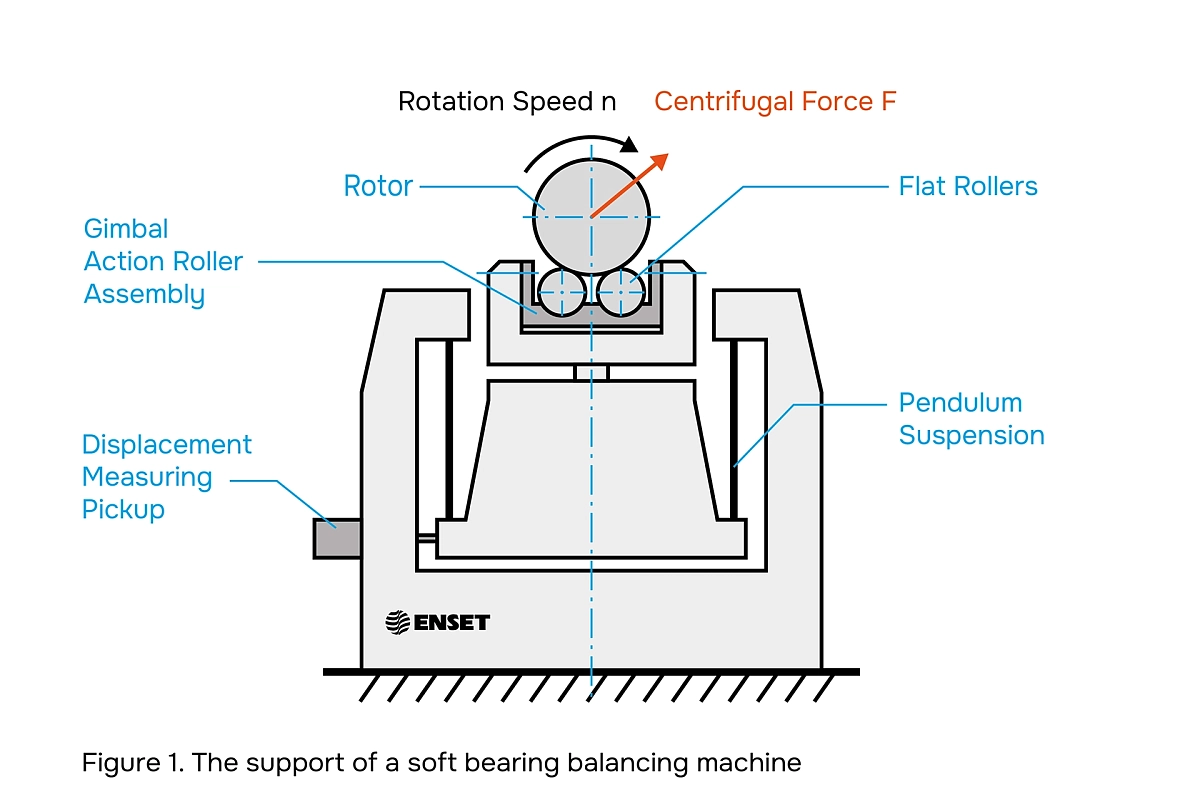

The natural oscillation frequency of the supports of soft-bearing machines should be significantly less than the rotation frequency of the rotor when balancing on such machines. For this purpose, the supports of resonant machines are made malleable, as a rule, in the form of a pendulum suspension, which allows the oscillating system to swing freely under the influence of forces arising from the unbalance of the rotor during its rotation on the machine.

Figure 1. The support of a soft bearing balancing machine.

On soft-bearing machines the oscillation amplitudes (displacements) of the low stiffness pendulum suspension system are measured during balancing. Since oscillations occur in the post-resonant mode with low resistance, the displacement of each support is equal to twice the eccentricity of the axis of rotation of the rotor relative to its main central axis of inertia in the plane of the support, and remains unchanged when balanced at any rotational speed above the resonant one.

Displacement, velocity, and acceleration sensors (accelerometers) of various operating principles – inductive, piezoelectric, capacitive, electrodynamic, optical, and others – can be used to measure oscillation amplitudes in soft-bearing machines.

Advantages of soft-bearing balancing machines:

● Soft-bearing machines are undemanding to the quality of the workshop floor. They work on any surface, stand on simple levelling feet and they can be mounted even on thin inter-story floors.

● Machines for heavy (from 3000 kg) rotors of the soft-bearing type have a less material-intensive design, they do not require heavy supports and therefore weigh less than similar hard-bearing ones in terms of load capacity.

● Such machines can be manufactured in a mobile (transportable) design for transportation to the balancing location.

● The vibration system of soft-bearing machines is well isolated from vibration sources in the workshop.

● Gimbal action roller blocks assembly with cylindrical rollers leave practically no wear on the rotor journals during long rotation cycles on soft-bearing balancing machines.

Disadvantages of soft-bearing machines:

● The mechanical structure is complex, fragile and has many joints. The design of the pendulum suspension and roller blocks of a soft-bearing machine requires a delicate attitude, preventive maintenance, and the mandatory use of loaders for heavy rotors.

● Balancing on a soft-bearing machine cannot be done at very low frequencies (the rotation speed must be at least one and a half to two times higher than the natural frequency of the pendulum suspension).

● Balancing accuracy is limited by friction in the pendulum suspension and in the roller block joints, as well as by the sensitivity of the sensors, and does not increase with increasing of the rotation speed. The maximum balancing accuracy of machines with flexible supports is comparable or lower than that of modern hard-bearing machines.

● For soft-bearing machines, the measurement cycle time is increased due to the need to unlock the machine supports after the rotor reaches the balancing speed and then wait for steady state oscillation of the machine suspensions before starting measurements.

● When balancing different rotors, the efficiency of the soft-bearing machine decreases significantly due to the need for calibrating the measuring system using the trial runs method for each new rotor size.

● Due to the need to use gimbal action roller blocks assemblies, it is impossible to use cantilevered rollers for rotors with short or hidden journals on a soft-bearing machine.

● Rotors with high initial unbalance cannot be balanced on a soft-bearing machine.

● A limited weight range of rotors could be balanced on a soft-bearing machine of the given capacity.

Hard-bearing machines (machines with rigid supports)

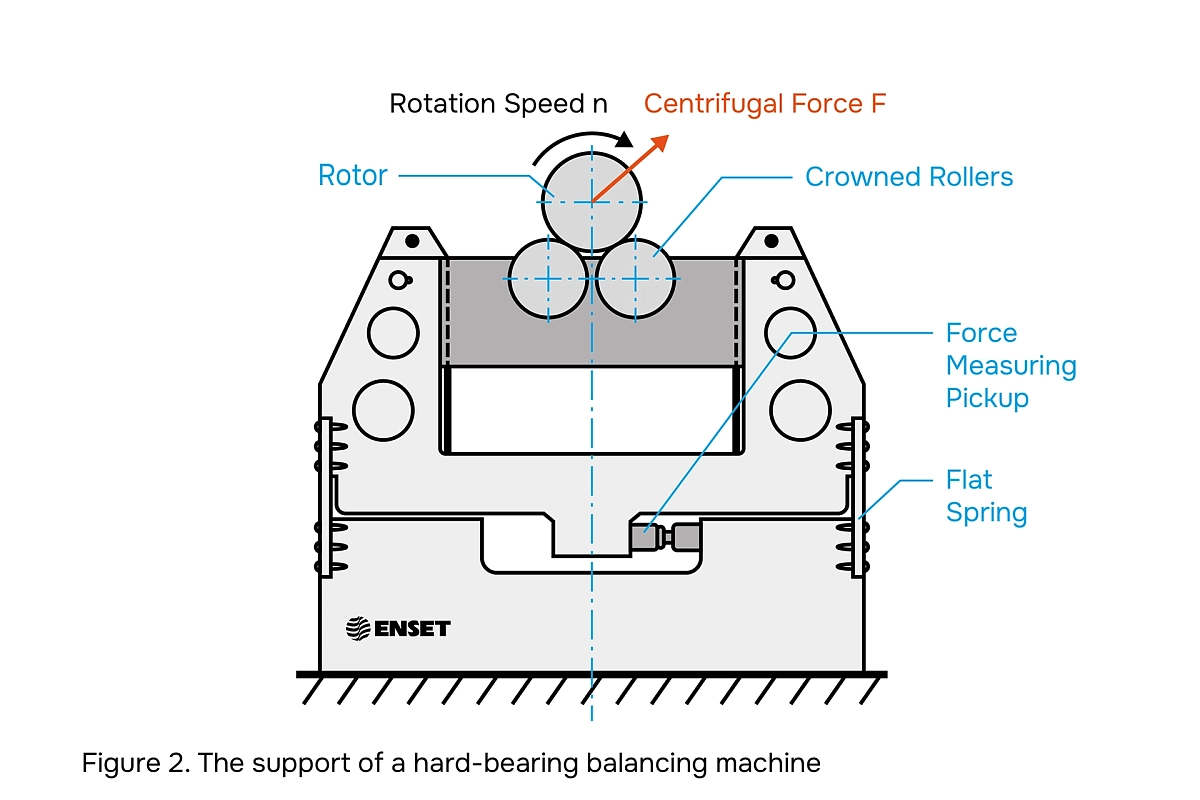

The resonance frequency of the supports* of such machines should be much higher than the rotation frequency of the rotor while balancing. For this reason, the supports for these hard-bearing machines are made in the form of rigid frame structures, especially in the direction perpendicular to the axis of the rotor.

Figure 2. The support of a hard-bearing balancing machine.

On hard-bearing machines, when balancing, the forces caused by the unbalance of the rotor during its rotation are measured.

The magnitudes of these forces are proportional to the square of the rotation speed of the rotor, thus, with increasing rotation speed during balancing, the accuracy of measurements of unbalances increases.

Different types of force sensors can be used – resistive (strain gauges), capacitive, piezoelectric, optical, inductive ones. However, piezoelectric sensors have recently become the most widespread in hard-bearing machines due to the active development and improvement of electronics processing their signals.

* more precisely, we are talking about the natural frequency of the oscillatory system “support+rotor".

Advantages of hard-bearing balancing machines:

● Reliable, rigid and simple design of the supports, requiring virtually no maintenance and allowing shocks and overloads.

● The balancing cycle runs quickly (no need to unlock the oscillating support systems and wait for steady-state oscillations, as on a soft-bearing machine).

● Thanks to the permanent calibration of the hard-bearing machine, the adjustment to a new rotor type is done quickly by entering the geometric parameters of the rotor into the measuring system.

● Balancing is possible at any rotation speed – from 80 up to 30,000 RPM and above.

● Wide range of rotor weights balanced on a single machine.

● The higher the rotational speed, the higher the measurement accuracy, but even at low rotational speeds it is sufficient for most applications.

● The supports of the hard-bearing machine provide rigidity close to that of the rotor bearings in the machine – this allows for faster and more accurate balancing of non-rigid (semi-flexible and flexible) rotors, as well as reliably checking the balancing quality at the operating speed (rev up the rotor and make sure that there are no vibrations).

● Hard-bearing machines are excellent for balancing cantilever rotors with the center of mass outside of the supports base (using force clamping rollers).

● It is easier to install any additional support balancing equipment - rollers, supports, beds, spindles, etc.

● Hard-bearing machines are capable of handling rotors with large initial unbalance (you just lower the balancing speed for such rotors).

● Hard-bearing machines allow for the correction of unbalances associated with the application of forces to the rotor (drilling, milling, grinding, welding, etc.), without fear of damage to the supports or sensitive components of the machine.

● Rigid supports allow the use of cantilevered rollers for rotors with short or hidden pivot points in the body.

Disadvantages of hard-bearing balancing machines:

● Heavy-duty machines (over 500 kg) require attachment to the concrete workshop floor using anchor bolts. Very heavy-duty machines (from 30 tons) require a massive separate foundation.

● There may be some deterioration in the accuracy of the hard-bearing machine when installed on thin inter-storey floors with voids under the floor covering.

● Hard-bearing machines use rollers with a crowned surface. And, although the radius of this surface is quite large, contact patch with the rotor still has a fairly limited area and some wear may occur on soft (non-heat-treated) journals during prolonged rotation of the rotor. It is worth noting that when balancing on a hard-bearing machine, there is no need to rotate for a long time – the job is usually done in 2 runs (including proving run).

● Theoretically, it is possible for vibration sources in the workshop to influence the readings of a hard-bearing balancing machine. This problem is extremely rare and is solved by slight adjustment of the rotation speed during balancing.

Below, we will evaluate both types of machines using a table with scores for each factor that can influence the choice of a machine for specific application conditions.

Table 1. Comparison of characteristics of different types of machines

|

Characteristic

|

Soft-bearing |

Hard-bearing |

|

Accuracy |

***** |

***** |

|

Reliability |

*** |

***** |

|

Setup time for a new rotor type |

* |

***** |

|

Measuring cycle run time |

*** |

***** |

|

The range of rotation speeds during balancing |

*** |

*****

|

|

Versatility for different rotor types and weights |

*** |

***** |

|

Capability to handle large initial unbalance |

** |

***** |

|

Endurance to force applying unbalance correction methods on the machine |

*** |

***** |

|

Ease of installation |

***** |

** |

|

Mobility |

**** |

* |

|

Balancing of semi-flexible and flexible rotors |

**** |

***** |

|

Isolation from vibrations in the workshop |

***** |

**** |

|

Wear on the rotor journals |

***** |

*** |

|

Machine weight |

***** |

*** |

|

Maintenance |

** |

*****

|

|

Average score |

3,53 |

4,20 |

Conclusion – if you need a machine for installation on a thin floor or a floor where it is impossible to use anchor bolts or set up the foundation, if you need a machine that will be moved frequently, or you need to limit the weight of the balancing machine for some reason, then your best choice is a soft-bearing machine.

In all other cases, the advantages of hard-bearing machines are so significant that it becomes clear why such machines are the obvious choice for most customers worldwide. That is why the world's leading manufacturers currently offer mostly hard-bearing balancing machines in their catalogs, leaving soft-bearing machines only as rare niche solutions.

For additional information, as well as for help selecting balancing equipment, you can contact ENSET by phone: +7 960 442 73 51